Get Started for FREE

Sign up with Facebook Sign up with X

I don't have a Facebook or a X account

| Tags |

|---|

Your new post is loading... Your new post is loading...

Your new post is loading... Your new post is loading...

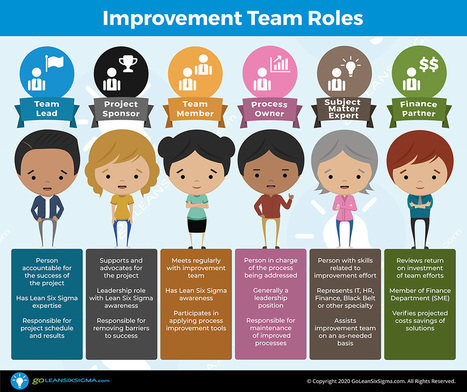

Lean Six Sigma Improvement Team Roles - Defining Each Role. If you connect with the right people then the odds of success go up—a lot.

Get the report “8 Top Tech Trends of 2020 that Every Digital Leader Should Embrace” Get your copy >> http://bit.ly/2PNg35S

Did you know that by 2023, AI-enabled automation in data management will reduce the need for IT specialists by 20%? Or that by 2024, 75% of large enterprises will be using at least four low-code development tools for both IT application development and citizen development initiatives?

Download the report “8 Top Tech Trends of 2020 that Every Digital Leader Should Embrace” and review the major digital trends of 2020, including: • Predictive intelligence accelerating decision-making • Low-code/no-code disrupting IT delivery processes • Conversational AI enabling truly customer-centric services • Blockchain delivering efficiency and disruption • Security & digital regulations impacting business strategies significantly

The report reveals practical insights from industry experts, and explains 8 main trends that will be shaping digital transformation processes in organizations in the upcoming year.

Our Online Classroom Training has 100% pass results with no cancellation or rescheduling and delivered by globally acclaimed trainers. Lean Six Sigma Green Belt Training Course Overview Lean and Six Sigma methodology is a combination of statistical theory, quality control knowledge and business...

Leading automotive supplier is seeking a Continuous Improvement Engineer to join their management team. As the Continuous Improvement Engineer, you will report to the Plant Manager and work with the ... More details on this job

Apply for HALLIBURTON US Conroe: Continuous Improvement Specialist - Lead Continuous Improvement Specialist Job in Conroe, Texas... |

From

vimeo

What's in the TLS – Theory of Constraints Lean Six Sigma approach to process improvement and how it creates results. Learn: 1. Improve the effectiveness of your Lean or Six Sigma Implementation using TLS Many organizations struggle with their continuous improvement (CI) efforts; achieving real bottom line results, whether in cost savings or increased revenues, has proven to be difficult. In spite of the widespread implementation of Lean and Six Sigma principles, poor results persist. The TLS process generates 15-20 times better performance than Lean or Six Sigma. This presentation will show the root causes of poor CI program performance and a systematic framework to create ongoing bottom line results. Via Philip Marris

- Experience working with (or developing in) RPA/RDA platform; specifically Pega, UI Path, Automation Anywhere, etc. - Experience working with business owners to source automation projects including: - Overseeing the documentation of current state processes pre-automation re-engineering those processes in light of the proposed automation & creating complete future state process. - Write-up the potential productivity gains in a cost benefit analysis document - Acting as a liaison between the technical team and the business. - Experience setting up and or running an Automation center of excellence Description: Lead and manage the implementation of effective business process solutions by communicating with key stakeholders to review business needs and translate vision into executable project plans. • Utilize process improvement subject matter expertise by gathering information from key stakeholders, documenting processes and overseeing project execution to monitor effectiveness and drive achievement of key stakeholder initiatives • Analyze and improve current processes by establishing and evaluating metrics and identifying gaps to recommend opportunities for translating department strategy into actionable project plans • Align project initiatives with business needs by understanding objectives and strategy of affected departments to ensure projects are timely, cost-efficient and within scope of department goals • Identify and recommend business re-engineering plans by collaborating with key stakeholders, developing process frameworks and adhering to established budget and timeline to implement a sustainable, streamlined model and ensure process longevity • Ensure long term effectiveness of process improvements by establishing, monitoring and evaluating key performance indicators and developing best practices and procedures to align with established business objectives • Deliver ongoing and final project reports by reviewing key performance indicators, summarizing information and communicating to key stakeholders to inform on effectiveness and share opportunities for continuous improvement • Manage budgeted resources by anticipating expenditures, accurately forecasting resource needs/costs and properly accounting for expenses to meet requirements and achieve fiscal responsibility • Contribute to a positive environment by demonstrating cultural expectations and guiding leaders to reward performance and value “can do” people, accountability, diversity and inclusion, flexibility, continuous improvement, collaboration, creativity and fun • Adopt our values in personal work behaviors, decision-making, contributions and interpersonal interactions; manage own career development by soliciting feedback and valuing other perspectives Bachelor’s Degree or equivalent combination of education and work experience 7 years relevant experience Preferred Qualifications Experience consulting on business process improvements; insurance industry experience; increasing levels of responsibility Six Sigma: Green Belt, Black Belt or Lean • Advanced working knowledge of project management and process improvement principles and best practices • Working knowledge of products and concepts related to the insurance industry • Advanced working knowledge of cost-efficient business transformation • Advanced working knowledge continuous improvement principals and best practices • Advanced working knowledge of business and management principles involved in strategic planning, resource allocation and coordination of people and resources Adjust plans, goals, actions or priorities to meet changing situations • Understand the principles underlying the relationship among facts and apply when solving problems • Anticipate obstacles, estimate time and resources needed for the completion of a project • Determine causes of operating errors and decide what to do about it; organize people, tasks and activities to yield efficient work flow • Conduct gap analysis of current state and desired future state • Manage multiple large-scale, complex projects Effectively present thoughts to key stakeholders to influence adoption of innovative recommendations • Work independently with little supervision or direction • Provide vision and think creatively and innovatively • Establish a high degree of trust and credibility with others • Adapt and be flexible in a complex changing environment

Senior Continuous Improvement Specialist - UAE National vacancy in Abu Dhabi with Inspire Selection. Search for more Senior Continuous Improvement Specialist - UAE National jobs in Abu Dhabi and other Middle East countries.

Attend the unique online event to get a comprehensive “8 Top Tech Trends of 2020” report and win prizes! Get your copy >> https://www.bpmonline.com/page/new-name?activity=leansixsigma

Dear Lean Six Sigma group members,

I am excited to let you know that bpm’online — the award-winning business software vendor leading in the space of CRM and low-code BPM — is changing their company name on October 30th during their biggest and most unique online show:

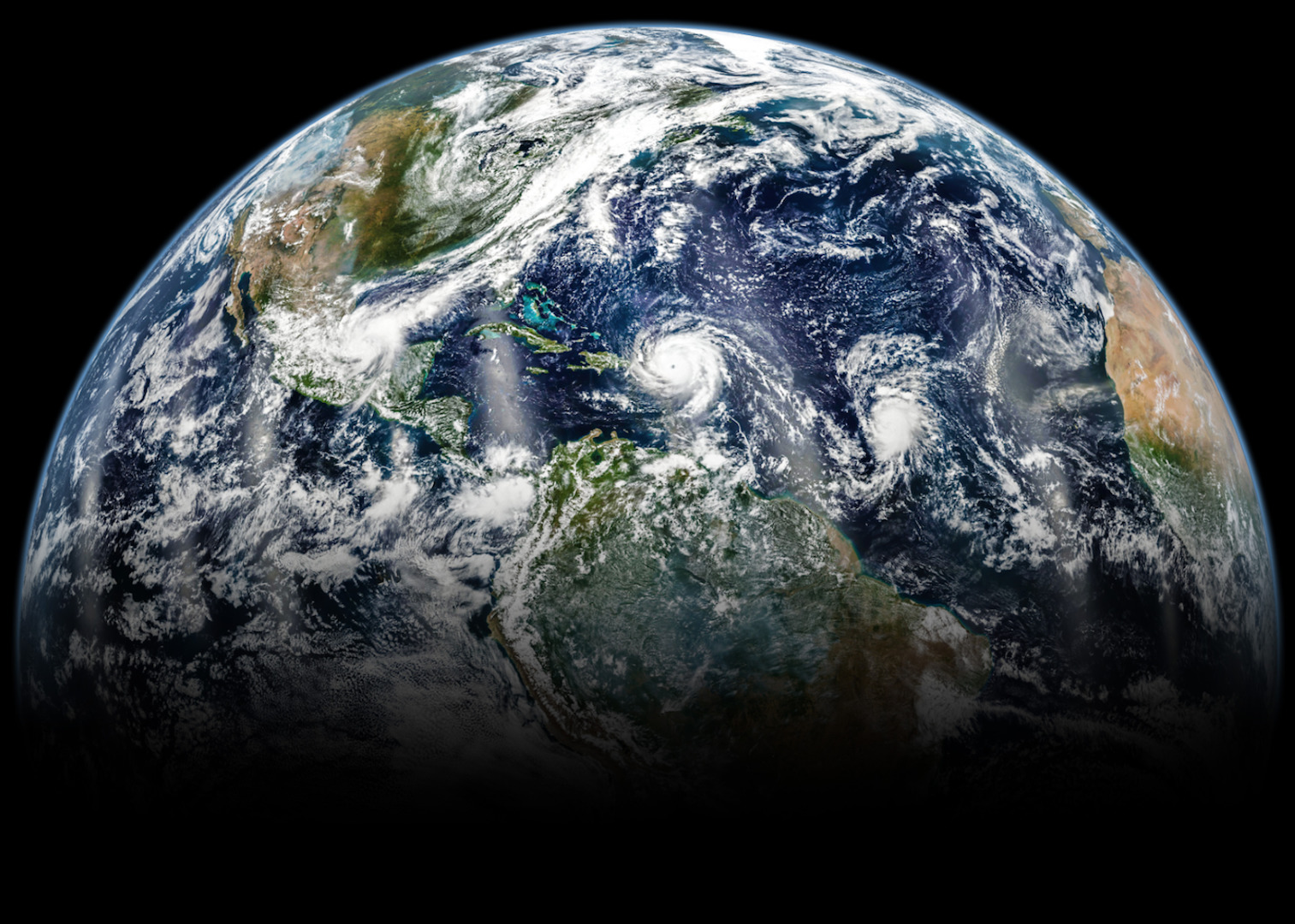

Bpm’online will literally announce their new name in the sky!

Register for this breathtaking online event and get a chance to receive festive prizes.

As a part of the company renaming celebration, bpm’online is having many giveaways, including a copy of their newest report “8 Top Trends of 2020 that Every Digital Leader Should Embrace.”

The report is available upon registration, and will be interesting to those who would like to explore the following trends for the upcoming year:

and many more.

Summary: The Continuous Improvement Engineer will be responsible for assisting in the development and implementation of the continuous improvement/lean vision for the organization. Lead improvement teams to solve problems, improve efficiencies, and establish a culture of continuous improvement across the organization. A leader in the implementation of best practices, the Continuous Improvement Engineer will drive the use of lean manufacturing principles and the planning/facilitation of strategic plans across multiple production lines. Essential Duties & Responsibilities: Assist in the planning and implementation of lean manufacturing strategies to achieve overarching global business strategy. Lead/coordinate lean manufacturing events/activities (i.e., Kaizen/continuous improvement, value stream mapping, statistical problem solving, etc.) as required including the planning of events and resources, training and leading teams, achieving event objectives and documenting performance. Provide leadership in continuous improvement efforts to improve efficiencies, reliability, ease of use & maintenance, to minimize changeover times, and to eradicate production losses. Coach & mentor less experienced lean practitioners including staff, supervisors and crew leads on continuous improvement methods and processes to establish a culture where tools and methods are utilized in a standard way to deliver improvements Develop lean leadership within local operations team to enable them to lead and execute their own lean activities within the plant according to the business strategy. Coach and support sustaining activities to ensure results are maintained for completed projects. Maintain positive work relationships with members of other teams to communicate effectively and to ensure compliance with cross-team responsibilities Required Skills Qualifications: Bachelor’s degree in a relevant Engineering discipline or equivalent (Industrial, Mechanical, Manufacturing, etc). 1-2+ years of progressive experience leading continuous improvement efforts. 4+ years previous experience in manufacturing; Demonstrated ability to learn, develop, and use lean tools to drive organization effectiveness. Ability to coach & train others to perform the same. Strong ability to successfully instruct/coach learners and to build collaborative working relationships Strong verbal and written communication skills to communication within all levels of the operations organization Excellent organization, multi-tasking, and prioritization skills; Strong computer skills in various software programs including Microsoft Word, Excel, PowerPoint, MS Project; Strong interpersonal skills to interact with diverse workforce Role & primary activities based out of the Hagerstown facility. Ability to travel 30%. Required Experience

Our Online Classroom Training has 100% pass results with no cancellation or rescheduling and delivered by globally acclaimed trainers. The Lean Six Sigma helps to improve the operational performance of employees so as an organization by reducing variances. |